Richmond Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is an old yet emerging methodology that popularity has risen and that’s used in manufacturing, businesses, and personal projects. It helps practitioners improve their processes and reduce waste. Lean Six Sigma can still be useful regardless of the circumstance, but to understand how this is possible, some history may be needed. At Lean Six Sigma Curriculum for Richmond High school Students of Virginia, our experts provide all details.

Lean Six Sigma is a mixture of Japanese management principles. However, it is primarily a combination of Lean and Six Sigma, and it can be traced back to the United States.

Before we can proceed, it is important to make this clear: LSS is not Japanese, despite its influence from Japanese methods.

Kaizen is the Japanese influence on the Lean Six Sigma methodology, and it is a great deal when it comes to how it made LSS become a reality. Now, to establish the basics, Kaizen encourages cooperation and commitment to continuous improvement, which is one of the main principles of Sigma.

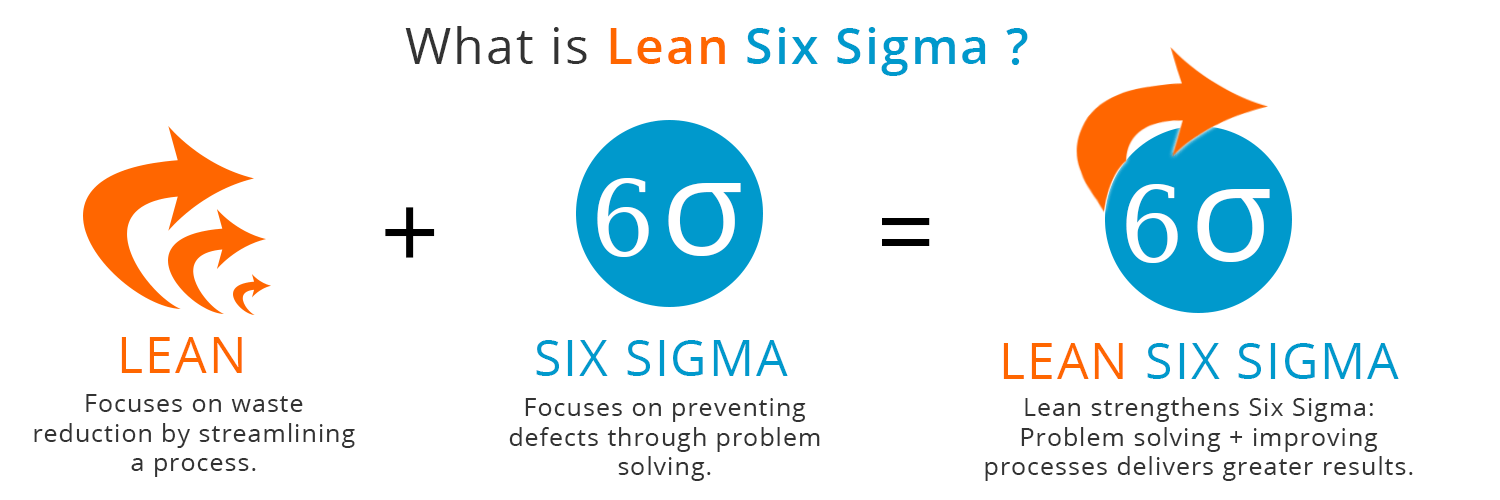

As we mentioned before, LSS is part of a methodology that combines two other methods, and thus, we should be focusing our attention on Six Sigma and Lean. Each contributes at its own level, and each has structures that can be combined to improve LSS.

Kaizen, LSS, and how it works are key concepts to keep in mind as well.

How Did Six Sigma & Lean begin?

It is important to understand the differences between Six Sigma and Lean and remember the fact that LSS is not the exact same as the former ones but more than them, even when it can be classified as a combination.

Because of its structure, Lean is also known as “Lean thinking.” It helps businesses and industries think about customers and improve their processes.

Lean can be traced back to Toyota and how it was integrated into Toyota Production System. John Krafcik was once a student at the company, and he was looking for a name to describe the TPS system that he had developed at the time.

On a whiteboard, he wrote down the differences between Toyota’s system and traditional mass production. He concluded that Toyota’s system needs less of everything to create value. This holds true for all Lean concepts.

Lean was quickly established by his conclusion and the whiteboard, and to keep it simple, the methodology is focused on reducing waste and non-value-added activities.

Lean is built upon its own principles and foundations. Understanding the customer is crucial to understanding the process waste stream and its value streams. Although it may sound like Kaizen, it’s not.

Six Sigma, an American-based methodology that dates back to the 1980s, will be next. Six Sigma was created by Motorola due to how the business had to face competitors from foreign companies in its early years. Motorola’s founder, Bob Galvin, had set a goal to achieve tenfold growth in five years.

The plan focused on global compatibility, participative management, quality improvements, global competition, and global cooperation. Six Sigma was quickly adopted by Motorola as the standard for all business processes since it increased cycles and produced better results.

Both approaches recognize that success can only be achieved through change. Six Sigma is a great addition to the Lean process, and LSS was born when both the Lean and Six Sigma principles were combined. Each technique should maximize its potential by following the existing structure, setting the basics, and adding value.

What’s Lean Six Sigma?

LSS has been used in many ways throughout history. It is designed to increase productivity and efficiency and reduce waste.

It is great to understand the principles and solutions of Lean and Six Sigma, and Kaizen. You can see both the benefits and drawbacks of LSS in this way.

Lean helps employees and companies better understand customers and prioritize customer needs. To achieve perfection, they can focus on the company’s value stream.

Six Sigma is committed to excellence and a culture that encourages efficiency and clean operations.

We’ll start with the basics of the principles and ideas of LSS and then show you how LSS works in practice:

- Learn how to reduce waste.

- Increase efficiency.

- Reduce errors.

- Reduce your risk.

- Time management.

- Lower costs equal higher revenues and better wages.

- Motivate employees.

- Innovation and leadership are two fundamental concepts that can be established in a company or individual’s mind.

Six Sigma & All Methodologies for Individuals & Companies

Lean Six Sigma Curriculum Pros of Richmond is available to assist you. This method is well-known in the field, and students of all levels can learn how to integrate LSS into their everyday lives and business processes, from high school to college.

We want you to reap all the benefits, so rest assured that besides students, workers, professionals, and even organizations or schools that want to instill a program can contact us to get access to training, certification, and more.